Prosthetic technology has made amazing strides in the last decade, and is only gaining speed. Hollywood has long been imagining versions of robotic body parts with incredible capabilities for a while now, and while human engineering can’t yet make these devices, prosthetics are getting smarter and more adaptive all the time.

The Goal

The goal in the industry, specifically with artificial intelligence, is to create intuitive limbs—human-machine interfaces embodied by a prosthetic device, that feel like a true extension of the body. A device that can decode the intuitive natural intention of the wearer would result in the most natural feeling prosthetic possible. AI is getting closer and closer to allowing the prosthetic user to reclaim total control over their movements.

For example, if the wearer of the device thinks about making a specific hand gesture, these new systems can interpret the signals coming from their body and turn them into electrical commands that actually make it happen. The idea is to create a prosthetic device that can figure out what the user’s muscles are saying and what they’re trying to do when they move and contract in certain ways.

Measuring Success

When it comes to accuracy in the world of artificial intelligence, engineers are looking for how well AI works with a static data set. Even today’s most advanced systems aren’t immediately successful. The AI prosthesis has to learn its wearer, as the wearer learns how to work with the prosthesis—which proves how smart these systems are. The wearer and their prosthesis co-learn each other and continue to work better together to make for a more natural extension of the wearer’s body.

The Future of Prosthetics

The nonprofit Amputee Coalition estimates that there are about 2 million amputees in the United States alone, and that number is expected to nearly double by the year 2050. Some 185,000 new lower-limb amputations occur each year. The driving forces behind the demand for this technology are aging populations, rising incidence of vascular diseases, as well as developments in artificial intelligence and machine learning.

Despite their booming potential, smart prosthetics are still a long way from becoming a common reality for people. This is due in large part to the relatively small population, the high costs, and the lack of reimbursement. Getting the technology transitioned out of the lab and into a company that will seek FDA approval is another hurdle.

Overall, the industry is exploding, and its future is extremely bright. For all the latest news in prosthetics, contact BioTech today.

Every year, roughly 10,000 infants and preschool age children are diagnosed with cerebral palsy, a neurological disorder that can impact the motor skill, movement, and muscle tone of the child.

There is treatment for cerebral palsy, though, in the form of braces and orthotic devices that help kids with cerebral palsy move around better than they’d otherwise be able to. With the right device, it’s even possible for a kid to walk.

Here’s what families need to know about finding braces and orthotic devices for children who are impacted by cerebral palsy.

Getting the Right Type of Orthotic Device

There are two different types of orthotic device: accommodative and functional. Accommodative orthotic devices are essentially over-the-counter devices that are prefabricated. They do provide some moderate support, but they’re not designed with the individual patient in mind.

Functional devices, on the other hand, are custom-built for the patient and are designed to provide more support to the child’s biomechanics. These types of devices are the best form of mobility aids for kids with cerebral palsy.

Building the Best Device

Cerebral palsy orthotic devices and braces are made of a variety of materials, ranging from carbon fiber to hard plastic, metal, rubber, or some combination of materials. They can be built in a variety of configurations, such as for the foot, as an ankle-foot orthosis (AFO), a knee-ankle-foot orthosis (KAFO), or even a brace running from the feet all the way to the torso.

We build the best braces by first taking detailed measurements of our patients. Then, we fabricate a device with durable materials and adjust the device until it it is a proper fit. But, each device has to be adjusted as the patient grows, which means the family will come to depend on a caring and friendly orthotist who can ensure the device remains effective as the child ages.

With proper care from an orthotist and a physical therapist, it’s possible for children with cerebral palsy to gain independence, mobility, and a better quality of life.

BioTech designs and manufactures orthotic devices for children suffering from cerebral palsy. We treat every patient with compassion and respect, and we work hard to deliver superior service and prosthetic devices that change lives. Recognize your possibilities. Contact us today for more information.

Prosthetic technology has come a very long way, even over the past decade. The trend now is trying to find a way to give the sensation of feeling to amputees through high-tech prosthetic devices, especially artificial arms and hands.

Researchers in France may have come up with the latest innovation: technology that lets amputees “feel” like their prosthetic limb is a part of their own body.

How Phantom Limbs Hold the Key

Some amputees dislike wearing their prosthetic devices because they feel like the device doesn’t “fit” their phantom limb.

And yet, the sensation of a phantom limb may hold the key to giving a sensation of feeling to an amputee through an artificial limb.

That’s what researchers at a university in France believe. They recognized that the prosthetic limbs currently on the market do not give a sense of touch to the wearer. The only “feelings” are what the wearer sees. It can be difficult to operate the limb unless the wearer is actively looking at it.

The researchers are essentially training the brain to go beyond just sight and incorporate touch into how they view their prosthetic device. Through tricking the brain, scientists have helped amputees “feel” their phantom limb growing into the prosthetic device - giving them the greater sensation of touch that they have been missing.

How the Technology Works

The technology is limited so far, but what it has been able to do is striking.

The researchers stimulate nerves in the stump of the subject’s arm while the subject wears an artificial arm and hand. This sends artificial feelings to their phantom limb’s fingertips. They also equip the wearer with virtual reality goggles that show how the phantom limb is “growing” into the prosthetic device.

The end result: wearers said they felt as through the artificial hand belonged to their own body.

The technology could be put into a portable setup that can provide therapy to amputees who are struggling to adapt to his or her prosthetic device. Therapy, in conjunction with advances in hardware and software that create sensations of touch and texture, can transform the way amputees interact with their prosthetic devices - and revolutionize the industry.

BioTech designs and manufactures prosthetic limbs for people suffering from limb loss. We treat every patient with compassion and respect, and work hard to deliver superior service and prosthetic devices that change lives. Recognize your possibilities. Contact us today for more information.

Most people do their homework when it comes to finding a doctor or a dentist. It shouldn’t be any different when looking for a prosthetist. After all, all of these professions are there to help take care of your body. You need the right prosthetic care just like you need the right medical or dental care.

But how do you find the right prosthetist for your needs? What should you look for? What kind of questions should you ask? How do you really know they’re a right fit for you?

What the Right Prosthetist Should Offer

Different prosthetists offer different things. But the best prosthetists offer:

- Decades of experience

- Dedication to patients

- Advanced prosthetic technology

- In-house prosthetic design and fabrication

- Enthusiastic providers

- Comfortable space

There are a couple of things on this list that most prosthetists can’t offer, and that’s advanced prosthetic technology and in-house prosthetic design and fabrication.

Most prosthetic providers don’t actually make their own prosthetics. They depend on other manufacturers to design, manufacture, and ship the devices to them. It’s important that your provider makes prosthetic devices in house because they’ll fit better and the process will take a lot less time, especially if you have to get your device adjusted frequently (and you will).

If they do make prosthetic devices, they need to use cutting-edge technology. A combination of laser scanning and 3D modelling with robotics ensures a better-performing, better-fitting device.

Asking the Right Questions

When interviewing the few prosthetists that you’ve narrowed down, you should ask a few important questions, such as:

- What is the process you use from start to finish to get patients fitted with the right prosthetic device?

- How do you make sure the device fits perfectly?

- If I have a problem with my device, how will you take care of it?

- What payment/insurance options do you offer?

- Are there any patients I could talk with to see how it is working with you?

You should feel free to ask any question you can think of. The right prosthetist will have the patience to answer all of them. This isn’t a decision you should take lightly, and they shouldn’t take it lightly either.

Take the time to talk to current and former patients. See what kind of care they’ve been given. Are they happy with their devices? With the service they’ve received? Would they recommend this prosthetist to one of their loved ones?

Finding the right prosthetist is a big decision. Take the time to go through the process and find a perfect fit who can give you a perfectly-fitting device.

BioTech Limb and Brace helps amputees recognize their possibilities by helping them live with a new prosthetic device. Learn more about our prosthetic fabrication and fitting services or contact us for more information.

Your body is the only one you’ll ever have. We need to give it all the support we can so it can support us as we go through our daily lives, no matter where we are or what we’re doing. Some of us have conditions that can interfere with “normal” movement, whether it’s due to an injury or a disorder.

In those cases, we have something that can really help us in our time of need, to live life fully, with as much mobility as possible: custom orthotic devices.

How Custom Orthotics Devices Help

A custom device - whether it’s a molded plastic foot orthosis to fit your feet or a knee-ankle-foot orthosis (KAFO) for your leg - has up to three purposes:

- Ensure proper range of motion (to the fullest extent possible)

- Provide proper support for the body part

- Correct abnormal alignment or curvature

Some of these goals are accomplished by helping your body bear its weight properly, such as the case with a shoe insert orthosis. Sometimes, we want to support a weaker limb, such as a leg, by equipping it with an orthosis designed to support the leg whenever it moves (or even is still, when the person is standing).

A device can only help, though, if it’s made properly, and the only way to do that is to create custom devices.

How We Create Custom Devices

At BioTech, we take great care to precisely and exactly measure your body so that we can craft something that is a perfect fit.

We have two main methods of getting an exact fit:

- Plaster casting

- Laser scanning

Plaster casting works by measuring your body part and creating a replica of the part in plaster so that we can get exact measurements.

Laser scanning works by using sophisticated equipment to scan your body part from all angles and upload the data into our computer. From there, we use specialized software to create a 3D model.

Often, we’ll combine the two so we make sure the fit is optimal, especially for more complicated situations.

The end result is an orthosis that fits you like a glove - which is the only way that a device can properly support you and accomplish the goals of the orthosis.

The next time you need an orthotic device, talk to a specialist provider who takes great care to create a custom-fitted piece just for you.

BioTech designs and creates custom orthotic devices for adults and children with a variety of conditions. Contact us if you have questions or want to schedule an evaluation.

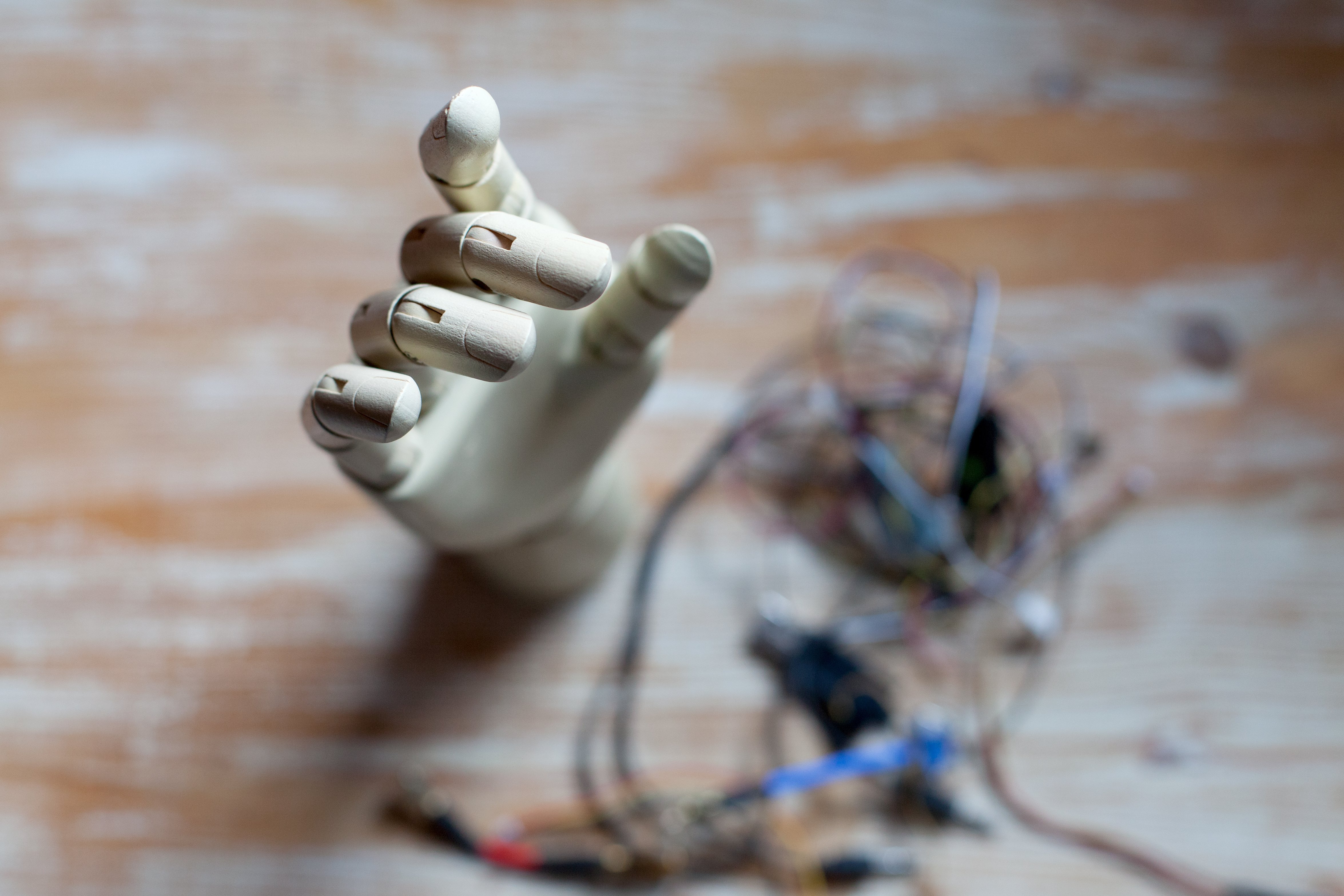

The holy grail of the prosthetic device world is a device that acts just like a natural limb through the thought processes of its user.

These “smart” devices aren’t here yet, but researchers are hard at work, and some of what they’ve come up with is pretty amazing compared to where we were only a decade ago.

The latest advance that is helping prosthetic device manufacturers and researchers is machine learning.

Machine Learning: Teaching Computers How to Think and Learn

Machine learning uses artificial intelligence to teach a computer how to “learn” - or get to a point where it can do new functions without having to be programmed to do those specific tasks.

By using this process, researchers and developers can get a computer to learn, as they go, how to better utilize data inputs and convert them into outputs. Put another way, the computer learns how to take what it’s being given and turn it into an action - and each time they do this, the process gets faster and more efficient until the actions are natural.

Developing Prosthetic Devices with AI

What researchers are doing is taking machine learning concepts and using them to develop computers and sensors that can take signals from a patient’s brain via electrodes on their stump and convert them into commands to their electronic prosthetic devices - and get better and better until the movement is natural.

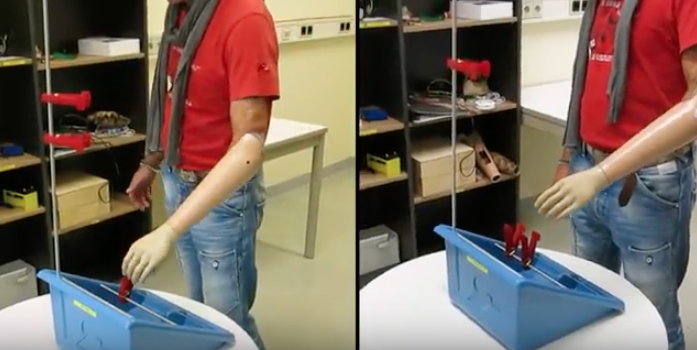

A video created by the Applied Surgical and Rehabilitation Technology Lab at the University Medical Center Göttingen in Germany shows how machine learning and AI helped create a prosthetic hand that is much more natural and smooth than the current models, which have slower, jerkier motions.

In the video, you can see a dramatic difference in performance as a user performs a simple task with the smart prosthetic hand versus current models without machine learning.

Technology is improving all the time. We talked previously about how researchers are developing prosthetic limbs that have the sensation of touch. By using machine learning and advanced sensors, developers can replicate touch and natural movement to create artificial limbs that one day will function virtually as well as our natural ones.

Contact us to learn more about prosthetic devices and let us share how we can help you live a normal and fulfilling live with your prosthetic limb.

Many of our patients who use our prosthetic devices are disabled veterans who are no longer in the military due to their disability.

Many of them have expressed frustration with transitioning from the military to civilian life, which can be hard enough for a veteran who doesn’t have a disability.

But, as we’ve helped them to learn, there are plenty of opportunities available to disabled veterans who want to find a new way to use their skills and experiences.

One of the most common ways disabled veterans have gotten back in the game and realized their potential is starting their own business.

Here, we’ll talk about how starting your own business can empower you to seize the day and live the life you want - even with your disability.

Veterans Have What It Takes: Courage

The veteran patients we’ve worked with, to a person, have something that every entrepreneur needs: courage.

Courage isn’t an absence of fear; it’s acting in the presence of it. And there’s a lot to fear when you’re starting your own venture, just like there’s a lot of fear when you face life with a disability.

What you’ll realize is that you have courage, and this courage is a must-have trait for a would-be businessperson. Courage is what will keep you moving forward even though the path seems intimidating and you may not be sure where you’re going or what you’re doing.

Courage sustains, not just in business, but in living life as a disabled veteran.

Veterans Know the Value of Teamwork and Leadership

You may have been in a leadership position when you were in the military, but even if you weren’t, you were part of a team and understand how teamwork and leadership go hand in hand to achieve a mission.

These traits are very difficult to find in the workforce among people who didn’t serve. Employers will pay a premium to find a hard-working team member, let alone a leader. As a veteran, you have an advantage.

Even if you don’t start your own business, you can parlay your experiences as a dedicated team member to the workforce. There is an employer out there who’d love to have you.

And if you are starting your own business, you’ll be able to put together a strong team because you know what it takes to get the job done when it comes to people.

The Government Will Help You

As a veteran, you will have preference for government contracts if you start your own veteran-owned small business (VOSB). A lot of veteran business owners have benefitted from this preference.

As a disabled veteran, you will get even more preference because you can qualify as a service-disabled veteran-owned small business (SDVOSB).

All of this comes with more opportunity for grants, loans, and other sources of funding to help get your business off the ground.

Above all, realize that life doesn’t end with the beginning of a disability. It’s just beginning. Your next journey is at hand, and it can be whatever you want it to be. Don’t let your disability get you down. See it as an opportunity to recognize the possibilities that lie before you - and seize them with courage, boldness, and determination.

BioTech helps disabled veterans with prosthetic devices, giving them the tools and support they need to live the life they want. Contact us for more information.

For those who have suffered from limb loss, the idea of a prosthetic device can be intimidating. No one plans on wearing one until they need one, and even when they need one, they may need to understand how it works before they get comfortable with the idea.

We run into this all the time and field a lot of questions from our patients about how their prosthetic legs and arms work - how they’re designed, how they’re supposed to fit and function, etc.

Here, we’ll break down how the components of your prosthetic device are supposed to work and make you more familiar with the design so that when it comes time to move, you’re ready to go.

Factors Behind Your Design

Not all prosthetic limbs are created the same. What you get depends on a few factors, such as:

- Body type

- Type of amputation

- Upper extremity

- Below elbow

- Lower extremity above the knee

- Below the knee

- Your body type

- The size, shape, and strength of the residual limb

- Your lifestyle

But generally speaking, prosthetic legs have the same function, as do prosthetic arms. They may just take different avenues to deliver that function.

The Components of Your Prosthetic Device

The most important component of a prosthetic arm or leg is actually the one you can’t see from the outside: the socket.

The socket is important because prosthetic devices have to be worn. You’re going to put a lot of pressure on that residual limb, and if the socket doesn’t fit right, it’ll cause a lot of pain and discomfort.

That’s why we go to great lengths to ensure a perfect fit for the socket, including molding, robotic carving (which is the most accurate fabrication process in the field), and 3D laser scanning.

It’s important to note that your residual limb will change over time. So, the socket has to be updated in order to match the contours of your body. The goal is a comfortable fit, which is something you absolutely should expect. No prosthesis should hurt when you wear it.

Other components include the joints. If you have an above-the-knee amputation, you’ll have two joints: the knee and the ankle. That doesn’t mean you’ll have an ankle that swings; sometimes it’s a fixed position that attaches the foot device to the leg itself. But your knee joint will be designed to allow the leg to naturally swing forward.

Knee and ankle joints (as well as elbow joints for upper extremity devices) can be computerized as well, which means a computer remotely controls the swing of the device as well as the shock absorption when you use it.

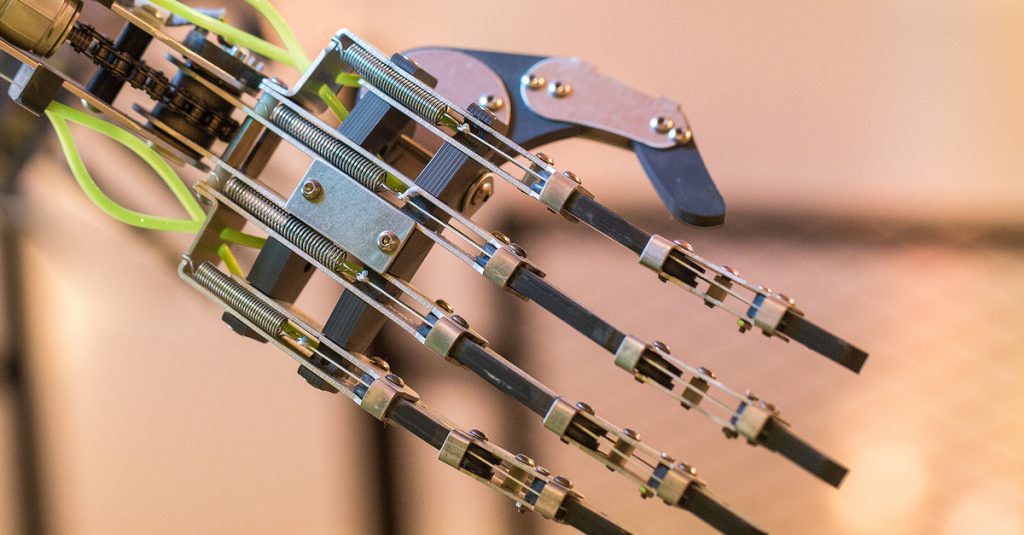

Finally, you may have a foot or hand attachment that can range from very basic to fully functional. Research is currently being done to expand the abilities of modern-day prosthetic devices to deliver functionality as close to biological capability as possible.

Now that you’re more familiar with your prosthetic device, you can begin the fulfilling process of getting fitted for your device and starting to learn to move and thrive in it.

BioTech helps amputees recognize their possibilities by designing and constructing comfortable and functional prosthetic devices. Contact the team for more information on your device and how you can take the next steps forward toward the rest of your life.

Technology is a wonderful, almost miraculous thing. It can enhance our lives and help us get back to normal after the trauma of an amputation. The best thing is that it’s constantly advancing and getting more beneficial every year.

At BioTech, we place a high premium on technology because we know that using technology only benefits our patients. We keep our fingers on the pulse of prosthetic device tech and share what we find with our patients so they’re informed about what we can do for them.

Here’s what’s changing the game for prosthetic devices today.

CAD-CAM Software and Devices Are Revolutionizing Fittings

When you get a prosthetic device, you need to be fitted for it. The traditional way of casting and measuring still works and can work well - but you’ll get a better fit for your prosthesis if you incorporate technology.

Computer-aided drafting (CAD) and computer-aided manufacturing (CAM) systems, called CAD-CAM for short, takes computer technology to the next level for prosthetic device design and creation.

In our office, we can scan your limb using a CAD-CAM scanner, upload it into our computer, and use powerful software to make modifications as necessary. Then, we feed that 3D model into a specially designed automated robot carving machine that carves an exact physical device using the design the software created - all from a real scan of your actual limb!

It’s amazing how precise, accurate, and comfortable your prosthesis can be using this technology, and we’re proud to use it on a daily basis.

Microprocessors Are Turning Prosthetic Devices Into “Smart” Devices

Prosthetic device manufacturer Otto Bock changed the game forever when they released their revolutionary C-Leg, which is controlled by tiny computers called microprocessors. This advance basically turned a regular, non-technological device into a “smart” device that helps better replicate a natural human limb’s motion using the power of computers.

A C-Leg adjusts the mechanics of the leg - particularly the swing - in real time as you walk. This enables a smoother, more natural gait that is also more stable and less tiresome. The microprocessors are working at the speed of light to modify how the leg moves so you’re getting a better experience with each step.

Now, the market is filling up with other microprocessor-controlled limbs, including some that are even trying to replicate the sensation of touch.

It’s an exciting time to be alive if you’re an amputee. What is possible now wasn’t possible 5 or 10 years ago, and what will be possible 5 or 10 years from now will astound us.

Contact the team at BioTech to learn more about how advanced technology in our office can help you find the prosthetic device to return normalcy to your life and give you a chance to recognize your possibilities.

The technology behind prosthetic limbs is constantly changing and evolving. One “holy grail” of prosthetic limb technology is to accurately and reliably simulate touch and feel of a natural limb in an artificial one.

Soon, according to researchers, that may be a very real possibility.

Researchers at the University of Illinois announced this month that they have designed an algorithm to give special prosthetic limbs the sensation of touch to their wearers.

These limbs are outfitted with electronics and sensors that, with the algorithm, can give amputees realistic sensations when they touch objects - something that has been elusive until very recently.

Of course, there are already advanced electronic prosthetic limbs that can provide some sensation of touch. However, these are relatively rudimentary and lack sophisticated algorithmic control to provide a consistent, ongoing, and accurate response.

The technology from the University of Illinois lab, though, can moderate signals from touching and handling objects and surfaces so that the sensation is prolonged and consistent.

The goal of the researchers is to give amputees limbs that feel like extensions of their bodies. That’s the goal of the prosthetic industry in general, but so far, accurate representations of touch have proven elusive. Plus, cost is an issue; advanced bionic limbs with that capability are prohibitively expensive for many.

The hope of the research team is to scale down the control module that handles the software and sensors so that it can fit within a normal-sized prosthetic limb and be affordable enough to be mostly or totally covered by insurance.

Reliable and consistent feedback is something that every amputee would love to have in their prosthetic limbs. With this new breakthrough, we’re one step closer to having that capability across all prosthetic limbs at some point in the future.

At BioTech, we’re all about using technology to improve the experience of our patients. That’s why we employ advanced methods to ensure a better fit and better performance for our patients who wear our limbs.

Contact us for a consultation and let us share how we can help you get the most of your prosthetic device so you can go above and beyond - and recognize your possibilities.